Possibilities of Contamination in Sterile Products

Contamination in sterile products is a serious problem in sterile manufacturing. It should be handled carefully to produce the quality products.

In pharmaceutical production, the term "sterile

products" is usually used to describe parenteral preparations. These are

products which are not meant to be

administered via oral route or alimentary canal, so do not benefit from the

protection of the immune system which the alimentary canal provides.

Administration of these drugs is done directly to the blood stream or various

body tissues.

Parenteral products include but are not limited to intravenous fluids, intramuscular injections, and optical solutions. Since these products will not pass through the digestive system, any contamination may mean very serious consequences to patients. For this reason, sterility assurance for such parenteral products is sacrosanct and must be achieved using standard good manufacturing practice. Every step must be taken to ensure that possibility of contamination in sterile products is eliminated.

Parenteral products include but are not limited to intravenous fluids, intramuscular injections, and optical solutions. Since these products will not pass through the digestive system, any contamination may mean very serious consequences to patients. For this reason, sterility assurance for such parenteral products is sacrosanct and must be achieved using standard good manufacturing practice. Every step must be taken to ensure that possibility of contamination in sterile products is eliminated.

Exclusion of Contaminants in Sterile Products

One thing is sure that

sterile products can be contaminated. They can cause more harm than good, or

even fatality to the patient if standards are not adhered to. In order for

sterile preparations to pass sterility assurance

tests, the following things must not be present in the product:

- Viable Microorganisms: Organisms which are capable of causing diseases must never be found in such preparation.

- Pyrogenic substances: These are fever-causing products of micro-organisms. Their presence in sterile preparation will mean we are "injecting fever" straight into the patients' bloodstream.

- Particles: If we can see particles in any of these preparations using the naked eyes, then that product is not fit for administration, and the entire batch must be destroyed.

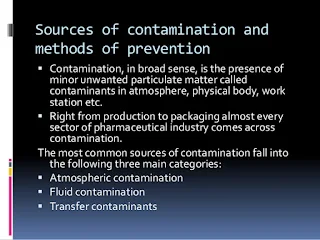

Sources of Contamination in Sterile Products

- Personnel: The operators have always been the most significant causes of contamination over the years, and several technological interventions have been deployed to r educe contamination from operators.

- Poor factory design: Air pressure in aseptic process rooms have to be at a higher differential to all adjacent process room; the floors must be even, without cracks and easy to clean; airflow through critical areas must flow in one direction only; temperature and humidity of the process rooms must be appropriately controlled; the factory must be pass re-qualification once every six months.

- Unrestricted access to production areas: While only staff who work in the sterile production facility should have access to the production areas, they should also have an industry standard changing room where they need to change into the appropriate protective gear before getting access.

- Area Cleaning: Poor cleaning and disinfection of work area are also a major cause of possibility of contamination in sterile products.

- Water supply: For such a facility, the water used should be distilled water (WFI), and the equipment for regular and copious production of this grade of water must be available.

- Production staff must be qualified, well trained and re-trained and maintain a high level of personal hygiene. They must always wear protective clothing and never touch the product with their bare hands during production.

- Facility design must only be done by experts in the field, to ensure that temperature and humidity can be appropriately controlled, in addition to the installation and use of the correct air filtration apparatus. UV air-locks and doors should be in place to separate areas with different sterility requirements. Laminar flow over work areas should have sufficient velocity to blow away particles from the packing area. Restricted access barrier systems (RABS) should be installed for use by the experts.

- Access to production area must be limited to well-trained production staff.

- The finishing of the production area should be such that all windows are easy to clean and do not allow dust to enter. Only stainless steel sinks are permissible. All floors, ceilings and walls must be easy to clean and totally free from cracks. Ventilation, pipework and light sources should be designed in such a way that they don't create recesses which are difficult to clean.

- The staff must maintain a high level of cleanliness and disinfect the facility as necessary with the appropriate grade chemicals.

- Distilled water (WFI) must always be used in production. Also, ensure that water is not allowed to gather and stay in areas where they encourage microbial growth and multiplication.

Comments

Post a Comment

If you have any doubts, please let me know